Whether you’re designing a PCB or need sourcing information for a specific component, IPC testing is crucial. IPC is the trade association that sets industry standards for PCBs, electronic product design software and documentation, and cable and wire harness assemblies.

IPC tester offers three levels of certification for those working in the electronics industry. These include Certified IPC Trainers (CIT), Certified IPC Specialists (CIS) and Certified Standards Experts (CSE).

Product Quality

Product quality is a term used to describe the characteristics or parameters of a particular product. These include chemical composition, physical properties (dimensions and dimensional tolerances), and mechanical and electrical properties.

Several factors impact the quality of a product, including technology, materials and labour availability. These can affect a company’s ability to create high-quality products that efficiently meet customer needs and generate revenue.

Product quality management effectively ensures that a company’s products are of the highest possible quality. This process focuses on planning, control, quality assurance and improvement.

The most critical factor in a company’s product quality management strategy is its understanding of how customers perceive product and service quality. Companies can obtain this information through surveys, interviews with current and potential customers, and field experiments.

Reliability

The Intergovernmental Panel on Climate Change (Ipc) is an international organization that produces assessments on global climate change. Governments commission these reports, and the findings in these assessments are interpreted and used by governments and others.

The IPCC has a reputation for being an independent body that doesn’t allow government officials to influence its reports, but some people argue this isn’t true. They say the summary reports are challenging to read because they don’t clarify what is being reported.

The IPCC’s evolving structures and procedures have allowed it to respond to a distributed governance structure, allowing the IPCC to develop a degree of independence from politics and to maintain legitimacy in the face of concerted efforts to undermine it. This capacity may become increasingly important as climate policy and implementation processes move into the future. It also reminds us that scientific expertise can be necessary for such processes.

Safety

Infection prevention and control in healthcare is an increasingly important issue. Those working in these environments must always have access to a reliable, rapid and portable testing device. Ideally, this should be part of the standard protective equipment employers and the general public require. This is especially the case when the infection prevalence rate is high or when rapid testing of patients/clients is required for COVID-19 or other transmissible diseases. The IPC tester is an excellent example of why it is crucial to have a device that can perform a wide range of tests and is designed with safety in mind.

Cost

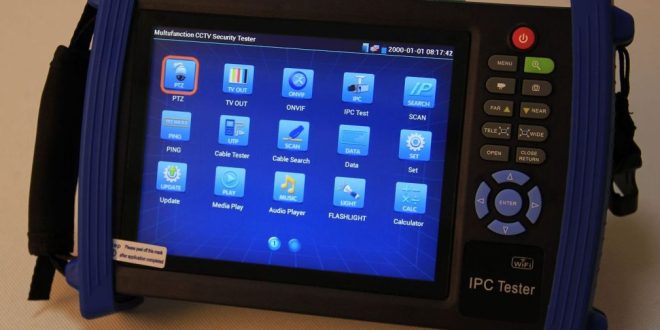

The cost of an IPC tester is one-factor affecting customers’ decisions on which product to buy. The cost of an IPC tester includes the hardware, battery, software and maintenance services. It is not cheap to purchase a quality ipc tester, but it is worth it when you consider the importance of your investment. A good ipc tester is essential for any networking or communication professional. It can help reduce the risk of costly misconnections and loss of data. It can also help to identify and trace cable faults such as cross-overs, miswired, shorts and opens.

Conclusion

IPC Tester can help manufacturers save costs by preventing defects and identifying faults early on in the production process. This prevents the assembly of faulty components onto the PCB, which would have to be discarded later. Discarding faulty components can be a significant expense for manufacturers, as it wastes time, resources, and materials. Moreover, if a defective device reaches the market, it can result in recalls, repairs, or even lawsuits, which can be incredibly costly for manufacturers. By detecting and rectifying defects early on in the production process, manufacturers can save a lot of costs and prevent any potential losses.

Naasongs.fun

Naasongs.fun