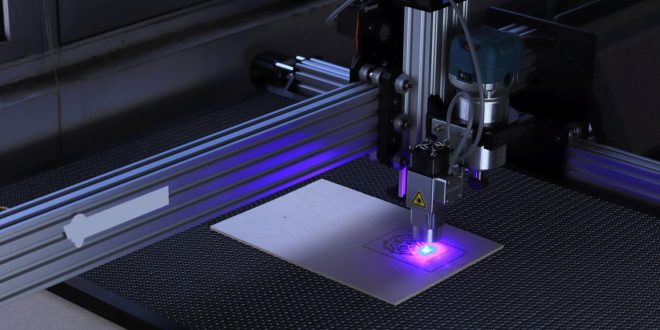

In the ever-evolving world of technology, laser engraving has emerged as a versatile and precise method for personal and industrial applications. From intricate designs on jewelry to marking serial numbers on industrial components, laser engravers have found their way into various sectors. Let’s delve into the fascinating world of laser engraving, exploring its technology, applications, and the innovative products available from Creality Falcon.

Introduction

Laser engraving, also known as laser etching, is a method of using laser technology to engrave, mark, or cut materials with unparalleled precision. It has become a game-changer in industries and hobbies that demand intricate designs and fine details.

Understanding Laser Cutting Technology

Unlike traditional cutting methods, laser cutting, often powered by a focused laser beam, stands out in its ability to melt, burn, or vaporize materials. This technology ensures clean and precise cuts, even in the most delicate and intricate designs, making laser cutters indispensable tools in various industries.

Types of Laser Cutters

CO2 Laser Cutters

CO2 laser cutters are versatile and widely used for cutting materials like wood, acrylic, and fabric. They are known for their ability to produce intricate details with a smooth finish.

Fiber Laser Cutters

Fiber laser cutters excel in cutting metals with high precision. They are commonly used in industries where intricate metal designs or precise cutting is essential.

Diode Laser Cutters

Diode laser cutters are compact and cost-effective, suitable for hobbyists and small businesses. They are ideal for cutting softer materials like paper and leather.

Applications of Laser Engraving

Personalization in Manufacturing

Manufacturers leverage laser engraving for adding unique serial numbers, logos, or personalized messages on products, enhancing brand identity and traceability.

Art and Craft Enthusiasts

Artists and craft enthusiasts use laser engravers to create intricate designs on various materials, pushing the boundaries of creativity.

Industrial Marking

In industries like aerospace and automotive, laser engraving is crucial for marking critical components with precision, ensuring compliance with quality standards.

Advantages of Laser Engraving

Precision and Accuracy

Laser engraving offers unmatched precision, allowing for intricate designs and fine details that traditional methods cannot achieve.

Versatility in Materials

From wood and leather to metal and acrylic, laser engravers can work on a wide range of materials, providing flexibility for different applications.

Speed and Efficiency

Compared to traditional methods, laser engraving is faster and more efficient, enabling quick turnaround times for projects.

Choosing the Right Laser Engraver

When selecting a laser engraver, several factors come into play to ensure the right fit for your needs.

Consideration of Materials

Different materials may require specific types of laser engravers. Consider the materials you’ll be working with to make an informed decision.

Power and Wattage

The power and wattage of the laser engraver determine its cutting and engraving capabilities. Choose a machine that aligns with your project requirements.

Software Compatibility

Ensure that the laser engraver’s software is user-friendly and compatible with the design software you prefer, streamlining the engraving process.

Popular Laser Engraving Products from Creality Falcon

Creality Falcon offers a range of laser engraving products designed to cater to various needs.

Falcon X1: Compact and Powerful

The Falcon X1 is a compact yet powerful laser engraver, perfect for small businesses and hobbyists. It boasts user-friendly features and high precision.

Falcon Pro-3: High-Speed Precision

For those seeking high-speed precision, the Falcon Pro-3 is an excellent choice. It’s equipped with advanced features to handle intricate designs efficiently.

Falcon Master Series: Industrial-Grade Engraving

The Falcon Master Series is designed for industrial applications, delivering unparalleled precision and durability for marking critical components.

How to Use a Laser Engraver Effectively

Safety Precautions

Before diving into engraving projects, prioritize safety. Use protective gear, ensure proper ventilation, and follow the manufacturer’s safety guidelines.

Setting Up Your Engraving Project

Prepare your design files, adjust the settings on the laser engraver, and secure the material in place before starting the engraving process.

Troubleshooting Common Issues

Understanding common issues like misalignment or power fluctuations helps in troubleshooting and maintaining the efficiency of your laser engraver.

Maintenance Tips for Longevity

Cleaning and Calibration

Regularly clean the lens and calibrate your laser engraver to ensure optimal performance and longevity.

Regular Software Updates

Stay updated with the latest software releases from the manufacturer to access new features and improvements.

Replacing Consumables

Replace consumables such as laser tubes or lenses as recommended to maintain the quality of your engraving projects.

Laser Engraving in the DIY Community

Laser engraving has gained popularity in the DIY community, empowering individuals to unleash their creativity on various projects.

Future Trends in Laser Engraving Technology

As technology evolves, laser engraving is expected to witness advancements, including improved speed, enhanced software capabilities, and broader material compatibility.

Conclusion

In conclusion, laser engravers have revolutionized the way we approach engraving, marking, and crafting. Whether you’re a hobbyist, artist, or industrial professional, the precision and versatility of laser engraving open doors to endless possibilities.

Frequently Asked Questions (FAQs)

1. Can laser engravers work on all materials?

Yes, laser engravers can work on a wide range of materials, including wood, metal, glass, and plastics.

2. What safety precautions should I take when using a laser engraver?

Always wear protective gear, ensure proper ventilation, and follow the safety guidelines provided by the manufacturer.

3. How often should I clean the lens of my laser engraver?

Regularly clean the lens of your laser engraver to maintain optimal performance. The frequency depends on usage and the environment.

4. Are laser engravers suitable for small businesses?

Yes, laser engravers like the Falcon X1 from Creality Falcon are compact and suitable for small businesses and hobbyists.

5. What are the future trends in laser engraving technology?

The future of laser engraving includes improved speed, advanced software capabilities, and broader material compatibility.

Naasongs.fun

Naasongs.fun